Advanced Bioethanol

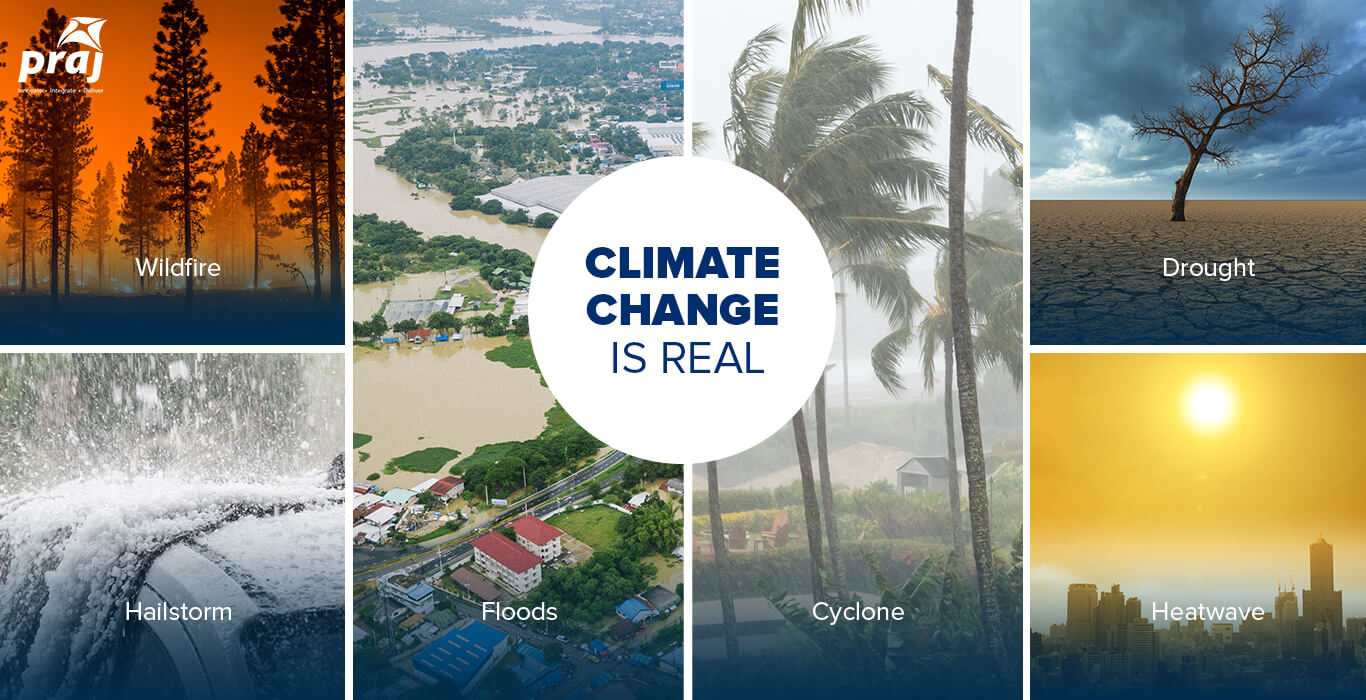

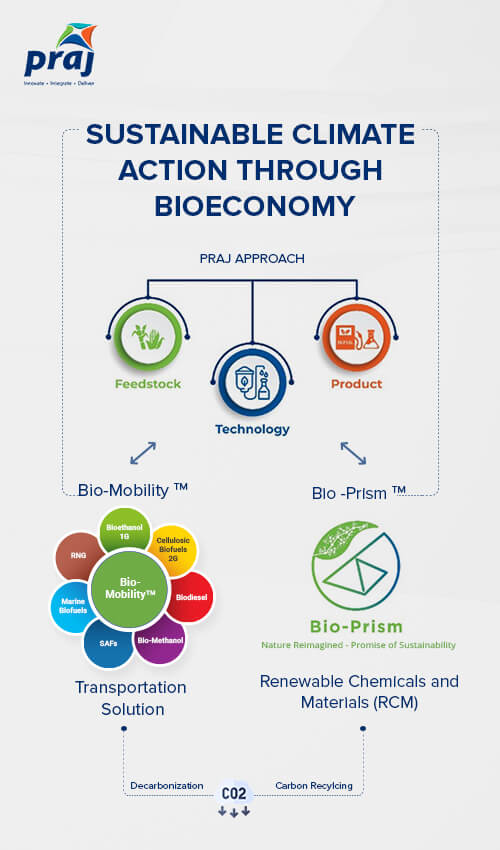

Renewable and clean energy are key drivers in decarbonizing the difficult-to-abate transportation and chemical industries for them to reach net zero emissions in 2050.

Globally, governments and industrial players are exploring different carbon-neutral pathways and technologies, which can contribute to meeting the decarbonization targets and can be sustainably and economically deployed at a commercial scale.

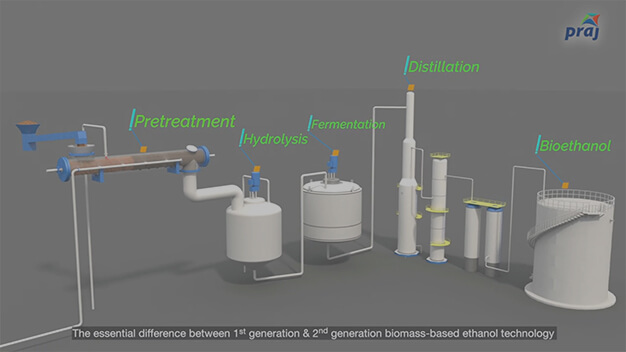

The conversion of non-food biomass like non-eatable agricultural and forestry residues into advanced bioethanol as drop-in fuel (also named 2G or cellulosic bioethanol) is one of the main pathways being selected across continents for policy frameworks to incentivize investments.

Renewable and clean energy are key drivers in decarbonizing the difficult-to-abate transportation and chemical industries for them to reach net zero emissions in 2050.

Globally, governments and industrial players are exploring different carbon-neutral pathways and technologies, which can contribute to meeting the decarbonization targets and can be sustainably and economically deployed at a commercial scale.

The conversion of non-food biomass like non-eatable agricultural and forestry residues into advanced bioethanol as drop-in fuel (also named 2G or cellulosic bioethanol) is one of the main pathways being selected across continents for policy frameworks to incentivize investments.

Unique Advanced Bioethanol Technology Offerings

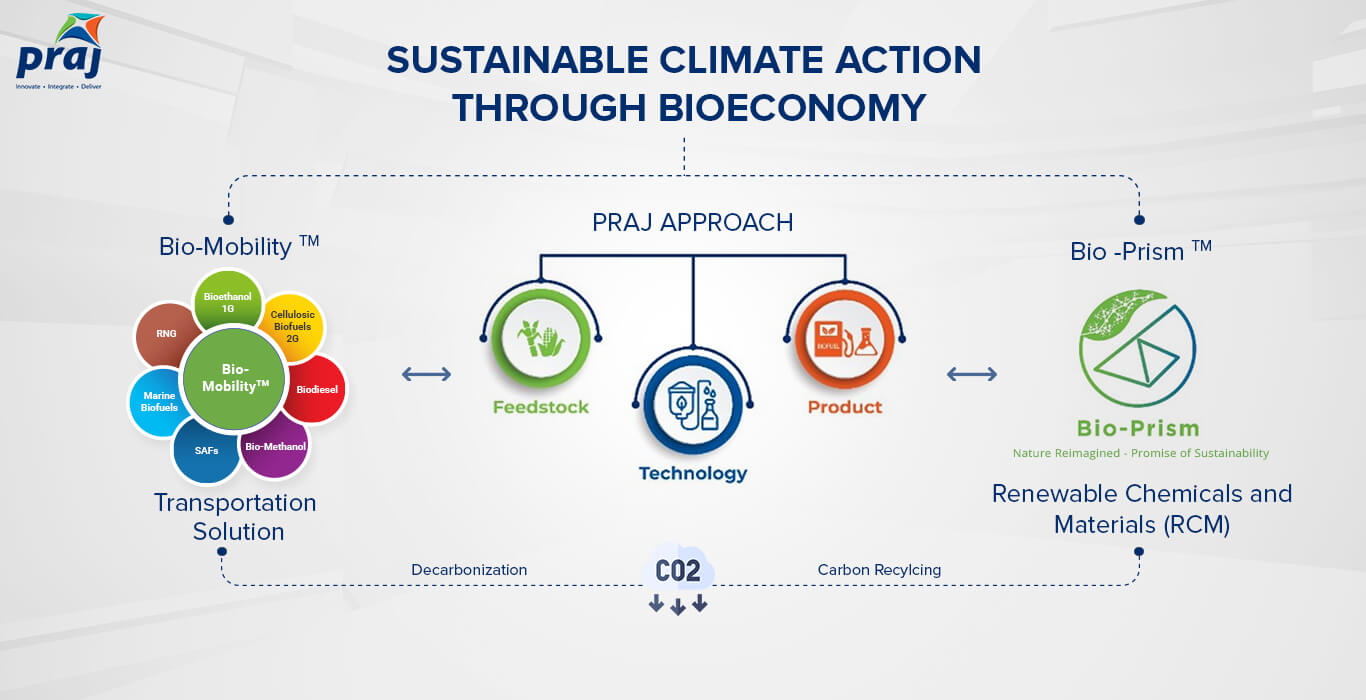

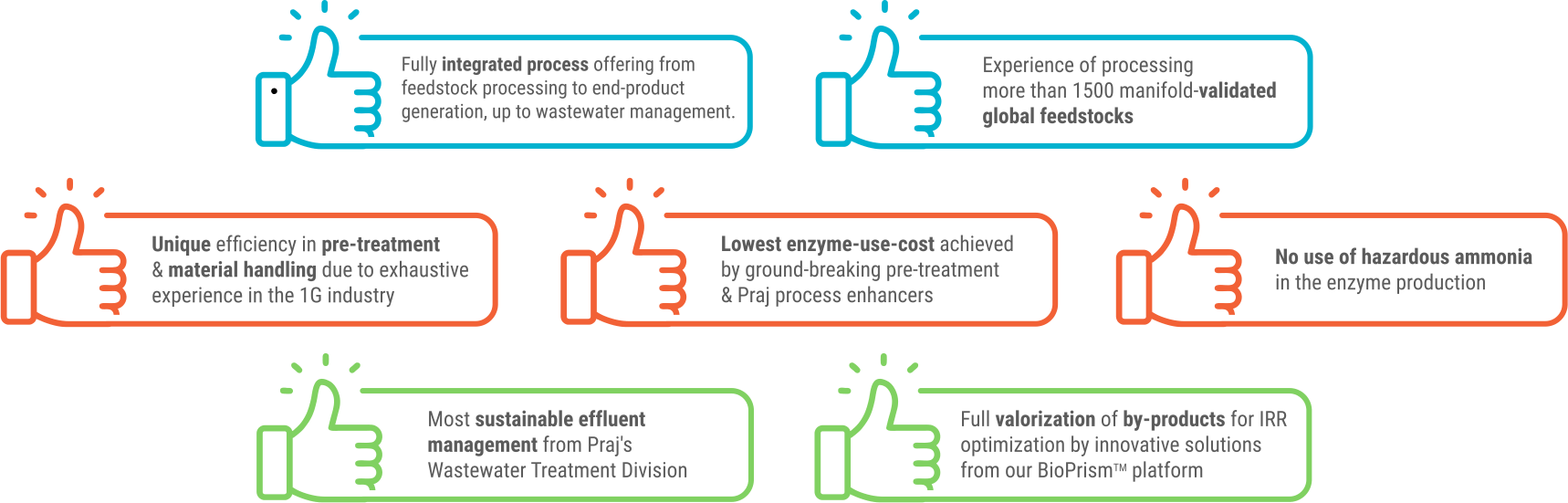

We at Praj, offer proprietary, proven advanced bioethanol technologies integrated with our in-house engineering, supply of optimized process equipment, and a broad range of consulting services.

We are uniquely positioned to leverage our 40 years of experience in the global biofuels industry and our knowledge from over 1000 designed and executed bioethanol plants, to deliver sustainable and best-in-class advanced biofuels solutions.

Our aim is to guide you to realize carbon-neutral and profitable biorefineries by accompanying you throughout the entire project life cycle.

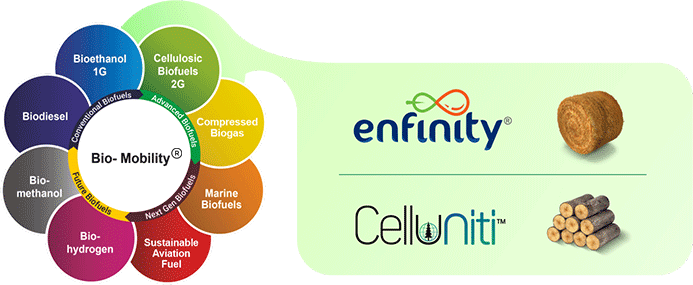

enfinity® & Celluniti™

Our Two Net Zero Technologies for Sustainable & Viable Advanced Ethanol Biorefineries

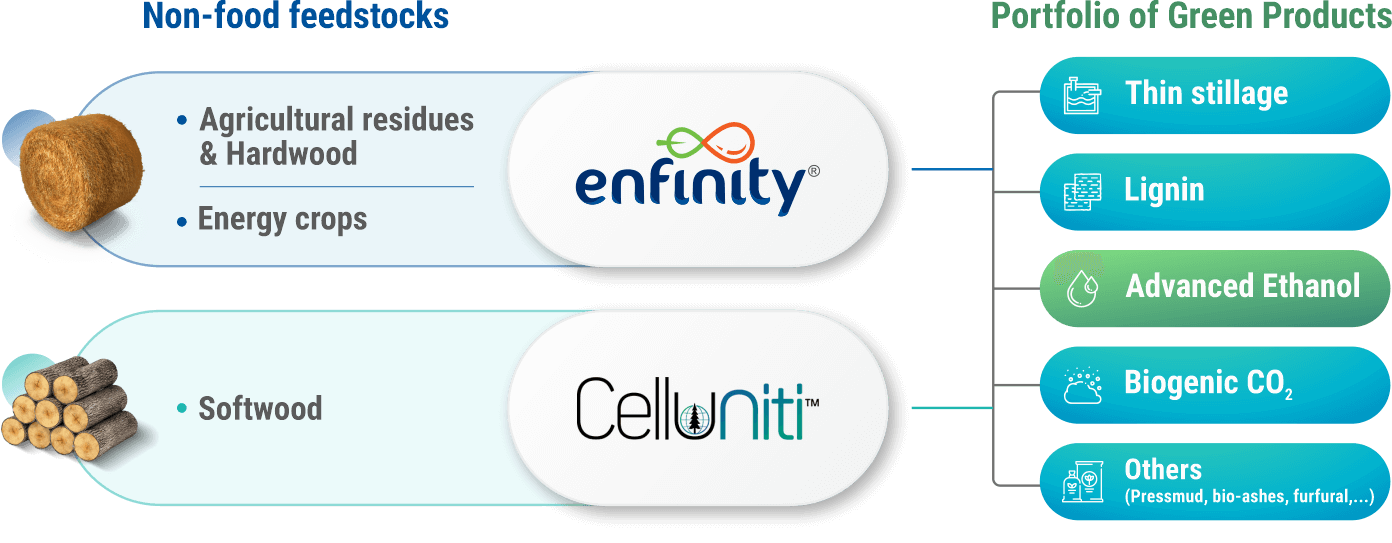

enfinity® & CellunitiTM are two different commercialized technologies from our Bio- MobilityTM platform. They contribute to solving the decarbonization problem in road transportation and the chemical industry.

Both proprietary technologies are the process backbone for commercial biorefineries of different sizes to produce advanced bioethanol and cellulosic sugars as well as the valuable by-products lignin, stillage, biogenic CO2 etc. from sustainable and inedible cellulosic feedstocks.

It depends on the feedstock, which of the two groundbreaking technologies to deploy.

enfinity® has been developed and optimized at an industrial scale for the input of agricultural residues like wheat and rice straw, corn stover, bagasse, and energy crops as well as hardwood and prospectively municipal household waste.

CellunitiTM is optimized and fully demonstrated on softwood feedstocks of non-food origins like pine, spruce, birch, etc. It developed jointly in collaboration with Sekab, a leading biochemistry company from Sweden.

Key Advantages of the enfinity® & Celluniti™ Technology

Flexible Platforms for Next-Gen Biofuels & Biochemicals

The end products of the enfinity® and CellunitiTM process namely advanced ethanol, cellulosic sugars, lignin, stillage, and biogenic CO2 can be chemical precursors and intermediates for next-gen biofuels like Sustainable Aviation Fuel (SAF) and bio-based Renewable Chemicals and Materials (RCM). To produce such products, the enfinity® and CellunitiTM biorefineries can be flexibly designed as upstream platforms. Praj Industries additionally offers a panel of technologies to produce SAF and RCMs within our BioPrism® platform.

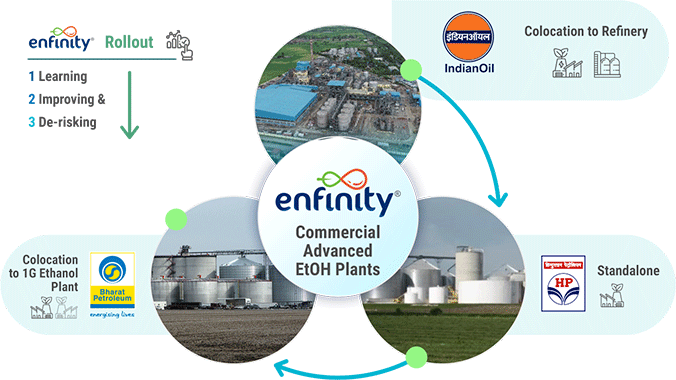

Rollout of our Advanced Bioethanol

Technologies

The rollout of the enfinity® technology is in full progress with the construction of 3 commercial advanced bioethanol plants, each of them with a production capacity of ~25000 tons of advanced bioethanol per year. The licensees are the Indian energy companies Indian Oil Corporation Ltd. (IOCL), Bharat Petroleum Corporation Ltd. (BPCL), and the Hindustan Petroleum Corporation Ltd. (HPCL).

The projects have different constellations,

- The IOCL project is co-located with its oil refinery in Panipat, Haryana.

- The BPCL project is an integrated 1G and advanced bioethanol complex in Bargarh, Odisha.

- The HPCL project is a standalone greenfield plant in Bhatinda, Punjab.

As the projects are between 9-12 months apart in commissioning, we comprehensively utilize the structured learnings from plant-to-plant de-risking the enfinity® technology.

Explore Our Advanced Bioethanol Solutions

Project Development Advisory

Along the entire value chain of your biorefinery project we offer you various professional consulting services to build a robust business case and maximize the internal rate of return of your investment.

Our professional advisory services range from tailored feasibility studies and feedstock qualifications to robust Capex and Opex estimations to make a sustainable development certain.

ARCH – Asset Retrofitting & Co-location Hub

Our dedicated multi-disciplinary engineering teams will exploit all possible value from retrofitting your existing assets when the advanced biorefinery is located within or co-located with your existing industrial facility.

We share our extensive retrofitting experience from 25 successful, large-scale bioethanol revamping projects and leverage this expertise for brownfield projects on/besides oil refineries and pulp & paper sites to provide optimized solutions.

Modularization & equipment supply

We deliver advanced biorefineries modularized compared to the typical onsite construction executed in the industry. The modularization approach offers a superior impact on the reduction of Capex as well as on total project time.

Through our business line CPES – Critical Process Equipment and Skids we deliver the plant in transportable premanufactured modules (incl. large loose equipment/items) which are manufactured in our own 4 equipment production facilities.

Till date, we have supplied 1500+ equipment and 300+ skids in 20 countries.

Expertise in Enzyme Optimization & Production

Praj has developed extensive know-how in enzymology and in the production process of sterile products in the biotech and biopharma industry inclusive of enzymes. The expertise consists of:

- Comprehensive research and development in enzyme optimization in our R & D center Matrix.

- Praj HiPurity’s engineering, and turnkey solutions for sterile biotech production plants.

- Praj HiPurity’s manufacturing of critical biotech and pharmaceutical process equipment such as microbial fermenters, smart bioreactors, sterile process piping, bio kill tanks, and inactivation systems, etc.

Our research and development team combines leading biologists and chemists from analytical science, scale-up to bioprocess engineering.