CellunitiTM

Project Development Advisory

Along the entire value chain of your biorefinery project we offer you various professional consulting services to build a robust business case and maximize the internal rate of return of your investment.

Our professional advisory services range from tailored feasibility studies and feedstock qualifications to robust Capex and Opex estimations ensuring sustainable development.

ARCH – Asset Retrofitting & Co-location Hub

Our dedicated multi-disciplinary engineering teams will exploit all possible value from retrofitting your existing assets when the advanced biorefinery is located within or co-located with your existing industrial facility.

We share our extensive retrofitting experience from 25 successful, large-scale bioethanol revamping projects and leverage this expertise for brownfield projects on/besides oil refineries and pulp & paper sites to provide optimized solutions.

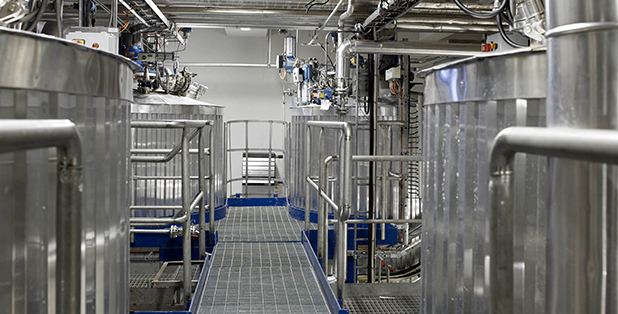

Modularization & Equipment supply

We deliver advanced biorefineries modularized compared to the typical onsite construction executed in the industry. The modularization approach offers a superior impact on the reduction of Capex as well as on total project time.

Through our business line CPES – Critical Process Equipment and Skids we deliver the plant in transportable premanufactured modules (incl. large loose equipment/items) manufactured in our four equipment production facilities.

We have supplied 1500+ equipment and 300+ skids in 20 countries to date.

Expertise in Enzyme Optimization & Production

Praj has developed extensive know-how in enzymology and the production process of sterile products in the biotech and biopharma industry, including enzymes. The expertise consists of:

- Comprehensive research and development in enzyme optimization in our R & D center Matrix.

- Praj HiPurity’s engineering, and turnkey solutions for sterile biotech production plants.

- Praj HiPurity’s manufacturing of critical biotech and pharmaceutical process equipment such as microbial fermenters, smart bioreactors, sterile process piping, bio kill tanks, and inactivation systems, etc.

Our R&D team combines leading biologists and chemists from analytical science, scale-up to bioprocess engineering.

Best-in-Class Advanced Bioethanol Technology based on Forestry Residues

Celluniti™ is the foremost proven biorefining technology enabling the conversion of a wide range of sustainable forestry residues into

- Advanced bioethanol and

- Valuable co-products such as lignin, stillage, biogenic CO2, and furfural.

The cutting-edge technology is unique in the industry, with a demonstrated, integrated production process, which is specifically designed for complex softwoods of non-food origin like pine and spruce. Softwood can be processed in several forms, e.g. as sawdust, wood chips, or pellets.

Softwoods, compared to hardwoods and agricultural residues, are the most recalcitrant biomass and require a specifically developed pre-treatment process and equipment beyond the market available pure steam explosion. Softwoods are available in abundance in the Northern Hemisphere like in Scandinavian and Northern European countries as well as in the USA and Canada among other geographies.

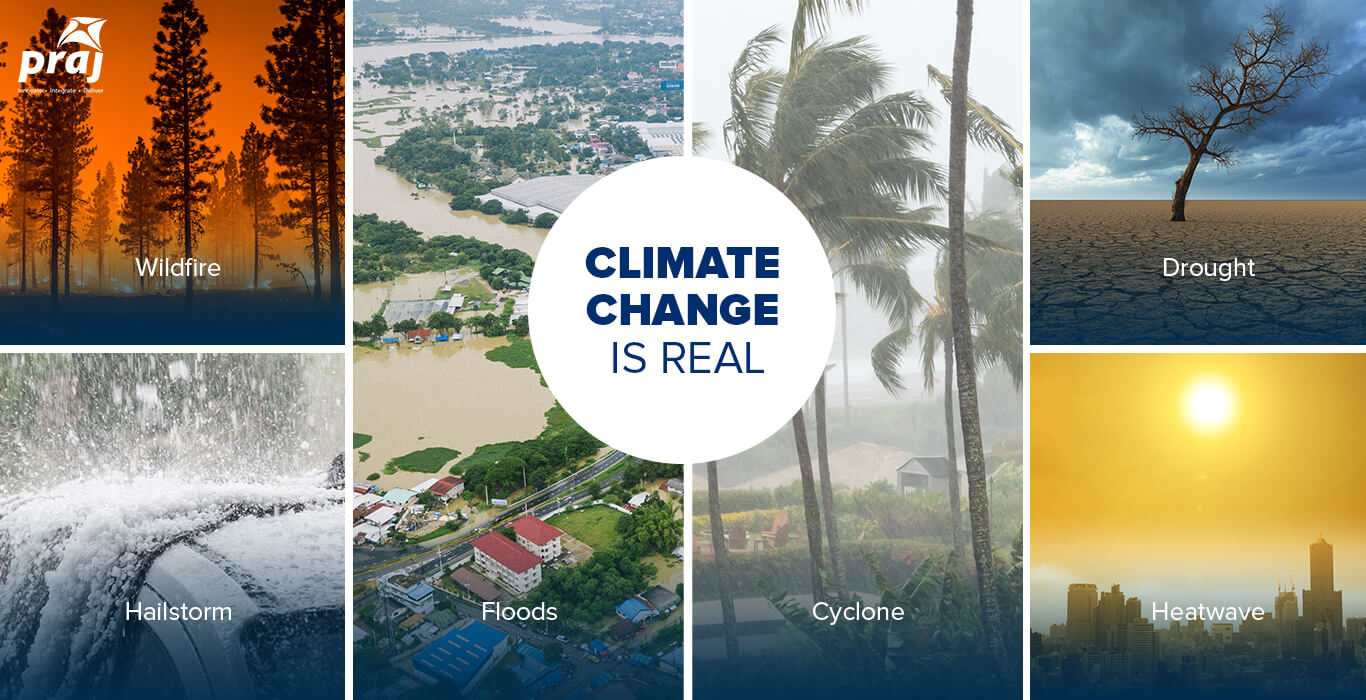

Celluniti™ can be scaled for a wide range of industrial production capacities. Depending on the project configuration, Celluniti™ can reduce greenhouse gas emissions by up to 100% compared to conventional fossil-based materials.

Celluniti™ will enable you to contribute to the fulfillment of mandates like RED III in Europe and LCFS in the USA.

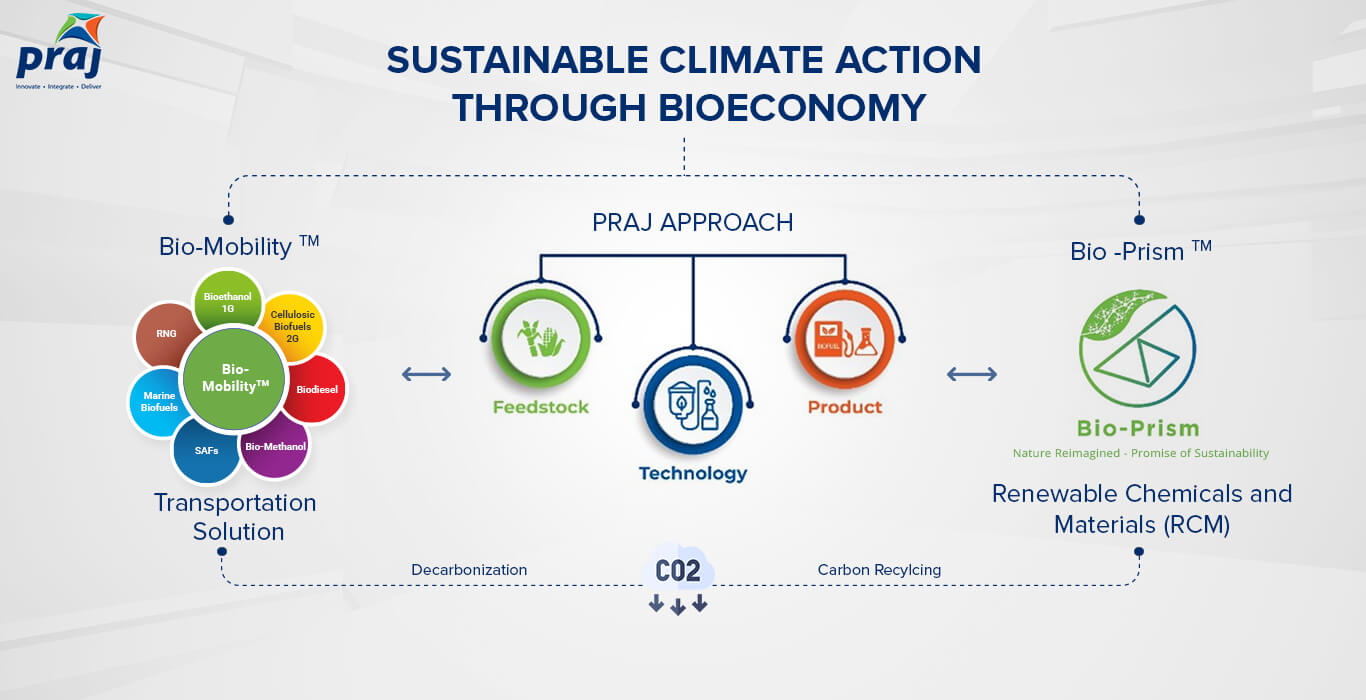

A Complementing Partnership - Praj & Sekab

Celluniti™ is the outcome of the strategic partnership of Praj Industries and the leading biochemistry company Sekab from Sweden, which is located in the middle of the High Coast Innovation Park in Örnsköldsvik, where forest ethanol has been produced for over 100 years.

The alliance brings Sekab's decades of developing unique technology with over 200 patents and Praj's global expertise in developing, optimising, integrating, and scaling bio-processing technologies.

Continuous & Dependable Operations in the Celluniti™ Demo Plant

The demo plant was inaugurated in Örnsköldsvik in 2004 as a national facility for the development of ethanol from forest raw materials and other lignocellulose materials.

It is an extraordinary facility and has been continuously running through shift work for almost one and a half decade.

- This means that the unparalleled technology has vast experience from over 50K hours of operations in the pre-commercial facility. It has created unique know-how and knowledge.

- An optimized enzyme loading through efficient pre-treatment conditions gives high yields that is particularly developed for the softwood feedstock.

- Today, the demo plant is operated in campaigns and test runs focusing on the development of large-scale projects for our customers.

Celluniti™ Process

Pre-Treatment

A specially developed pre-treatment method, which is designed to process more recalcitrant biomass to achieve high glucose yield.

Enzymatic Hydrolysis

It involves cleaving the polymers of cellulose and hemicellulose into sugar monomers using a customized cellulytic enzyme.

Ethanol Fermentation

It is the anaerobic pathway carried out by yeasts where sugars are converted into ethanol and by-products. Optimized yeasts convert both C5 and C6 sugars thus giving higher yields of ethanol.

Product Purification

Various innovative processes and technologies are developed and utilized that reduce energy requirements and provide self-sufficient energy operations.

Co-location, Retrofitting & Modularization

When your advanced bioethanol plant is supposed to co-locate to or retrofit a pulp & paper mill, a biomass CHP plant, or any other industrial facility, we will service you to optimize your existing assets from an early project stage. We are going even further, to deliver the majority of the Celluniti™ bioethanol facility in prefabricated modules, which is key for remote areas and an extremely cold climate, to increase the construction safety but foremost to significantly minimize the site work and commissioning time.

Our combined cross-functional engineering teams from Praj and Sekab will leverage joint expertise and know-how to help you realize a sustainable and profitable woody-based biorefinery project.