Co-product valorization

Praj offers systems to recover a number of co-products that give additional revenue stream besides ethanol.

CO2 Recovery System

CO2 generated during fermentation used to be emitted into the atmosphere. Not only CO2 can add to the revenues of an ethanol plant, its recovery also improves the sustainability.

Praj's skid mounted, cost-effective systems help recover food and industrial grade CO2 in compliance with the quality norms set by International Society of Beverage Technologists (ISBT). CO2 finds applications in food and beverage, metallurgy and welding, rubber manufacturing and several chemical processes.

Dryer Vapor Integration for Distiller’s Dried Grains with Solubles (DDGS)

In grain based distilleries, a major part of thermal energy is utilized for the production of DDGS. This energy is supplied in the form of steam which is condensed inside the tubes of steam tube bundle dryer thereby evaporating the moisture from wet cake and syrup mixture and drying it. Vapors from the dryer are generally vented into the atmosphere and are considered as waste heat.

Praj’s new integration technology consisting of special equipment for extraction of heat from dryer vapors cleans these vapors and enables utilization of this energy in the process either for liquefaction, distillation or evaporation, thereby reducing the overall energy requirement.

BioCNG

Biogas generated in the ethanol plants is used in boiler to generate steam by replacing auxiliary fuels like bagasse, coal, husk, wood chips etc. Steam generation from biogas plant is 5-6kg/m3 of biogas and the power generation is 2-2.4 kg/m3 of biogas.BioCNG can replace the LPG & CNG and is increasingly getting used as vehicular fuel.

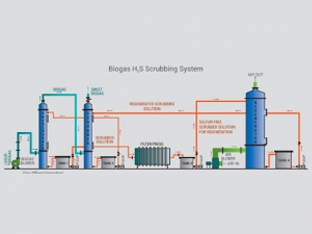

Praj offers complete range of solution for conversion of biogas to BioCNG. Our desulphurization (H2S scrubbing) system features minimum operating cost, no dilution of methane and acceptable levels of sulphur in BioCNG.