Celluniti Technology

Is a unique IP-protected technology for making biofuels and chemical products from biomass.

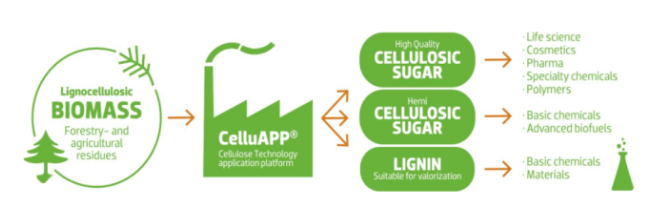

Praj and Sekab is a unique partnership with proven capabilities to develop, integrate and scale up advanced biofuel technology – CelluNiti Sekab E-Technology AB is part of Sekab Group, a Swedish Biochemical and cleantech company and has developed a technology (“CelluAPP”) to convert cellulose to sustainable sugars and bioethanol. Sekab provides know-how, patented processes and proprietary technology for the production of bioethanol from lignocellulosic biomass

Why Celluniti?

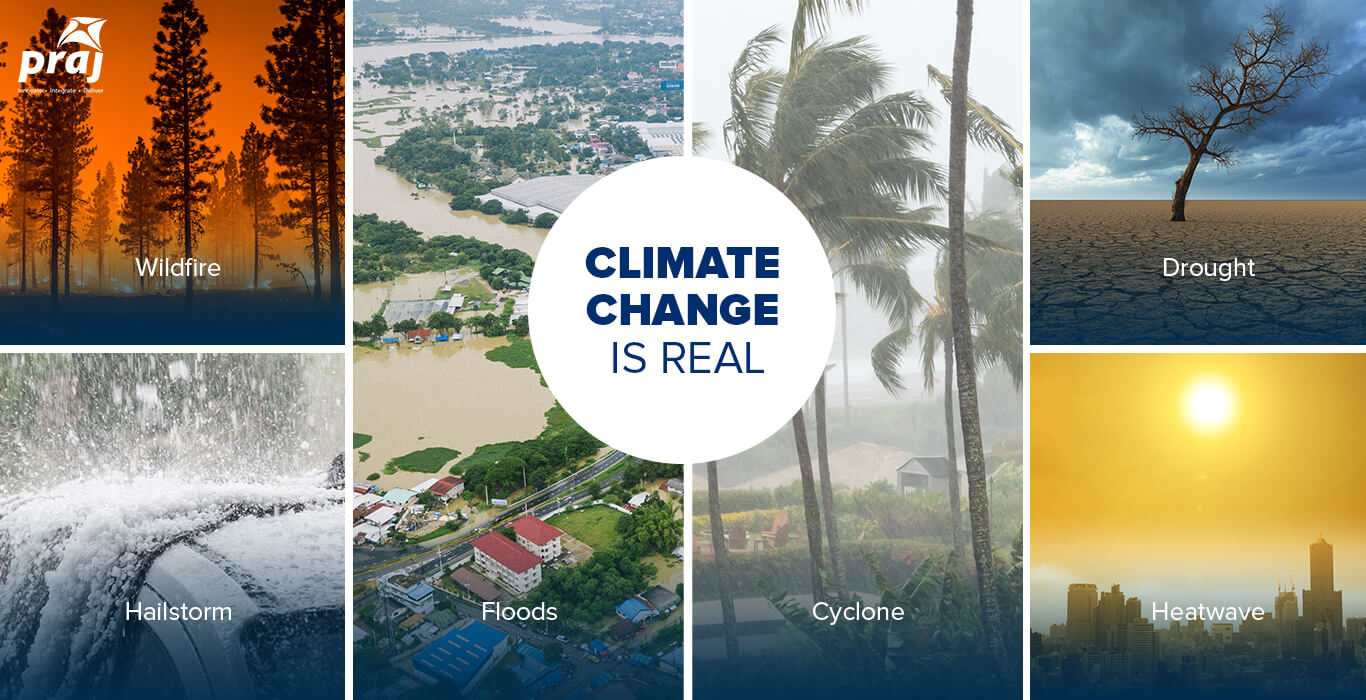

To combat the evils of climate change, the European Union has committed to ambitious greenhouse gas emission reduction targets through the European Green Deal. Valorizing and refining biomass is key to producing sustainable energy

The demand for advanced bio-chemicals is on the rise. In Europe alone, the need will grow multi-fold and only a small fraction of that production capacity is available.

The time to invest in producing advanced bio-chemicals to help mitigate climate change is now.

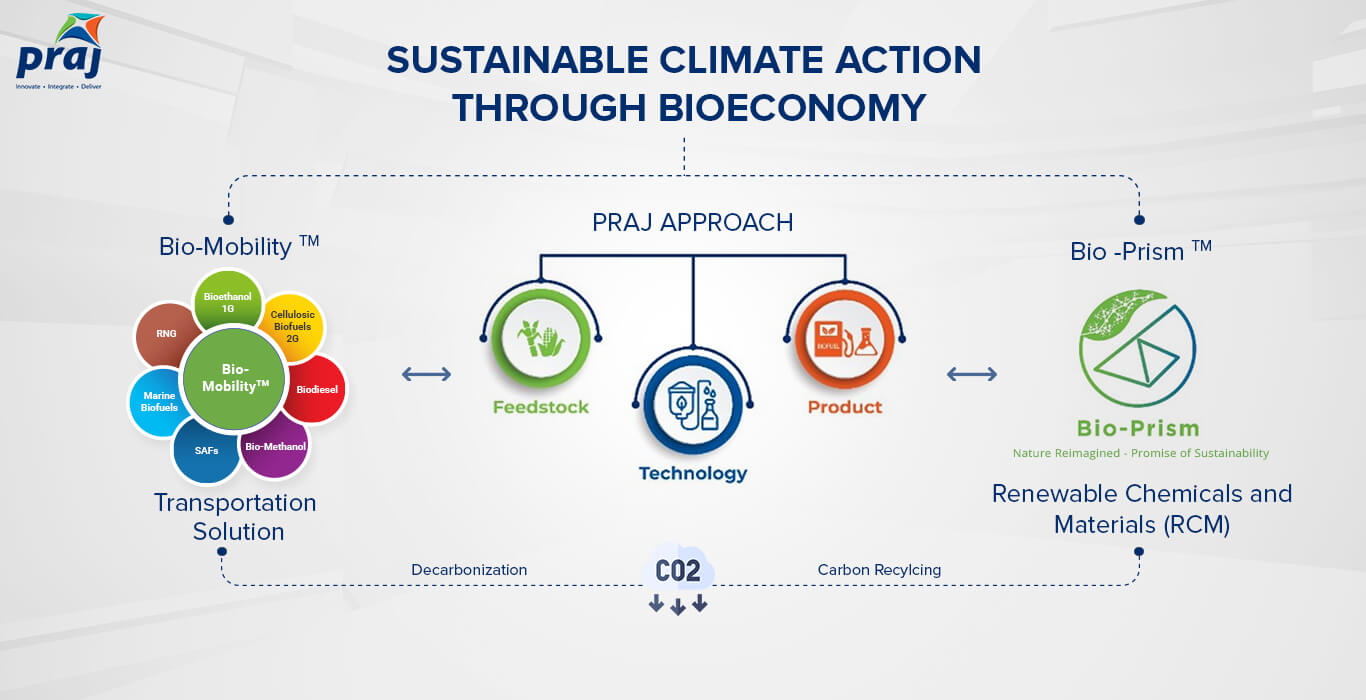

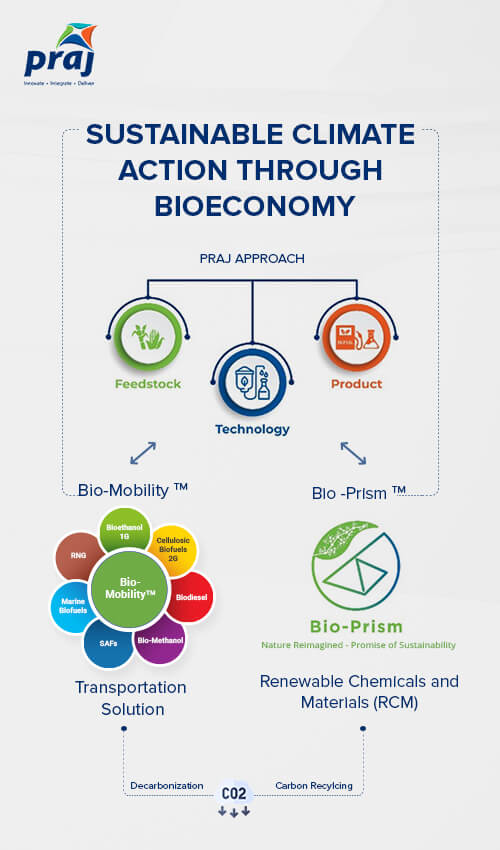

Together Praj and Sekab will offer sustainable solutions under CelluNiti technology that will support climate action by decarbonizing transportation.

At the core of this solution is Sekabs CelluApp technology of converting forest residue in the form of softwood to ethanol combined with Praj’s proven capabilities to develop, optimize, integrate & scale up advanced biofuel technologies.

Praj used its ‘enfinity’ platform to optimize, integrate and upgrade ‘CelluAPP’ technology to ‘Celluniti.’ Together we offer CelluNiti to the world!

CelluNiti makes it possible to refine almost any form of biomass into environmentally friendly, high-quality and commercially viable chemical products and raw materials such as cellulosic sugars, ethanol biogas and lignin.

This in turn can be used as climate-neutral and high-quality raw materials in the manufacturing of many of the everyday products around us such as cosmetics, hygiene articles, biofuels, plastics and pharmaceuticals

Praj’s offerings (Celluniti):

- Technology license and Process Design Package to produce advanced ethanol from forestry (softwood) residues including saw dust and chips.

Services

- Technical support during basic and detailed engineering

- Supervision services during plant installation

- Technical support during pre-commissioning and commissioning

- Technical support during normal plant operation

Technology Highlights

- Leveraged the extensive experience of 1st Gen technology (1000++ reference- 100+ countries - 5 continents)

- Simple and Robust

- End-to-End integration – Energy, water & substrate wise

- High on-stream factor

Process

Pre-treatment

- Efficient depolymerization thus high porosity to ensure best in class enzyme use

Enzymatic Hydrolysis

- Optimized enzyme consumption

Fermentation

- Fermentation efficiency is comparable to 1st Gen fermentation

- Effective mitigation of the impact of inhibitors

Distillation

- Low energy consumption as a result of heat integration

Ethanol Dehydration

- Praj’s EcoMol- Molecular Sieve Dehydration Technology offers multiple benefits including high ethanol dryness, longevity of sieve beds, ease of operations and lowest energy consumption

- Experience from 200+ references for ethanol dehydration units