Fermentation

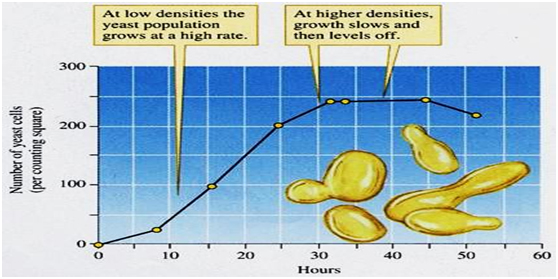

Fermentation is where the actual reaction takes places between feedstock and the yeast to form ethanol. It is of utmost importance that the process is infallible and closely monitored. Praj offers a range offermentation technologiescombining biochemistry and engineering.

HiFerm Fermentation

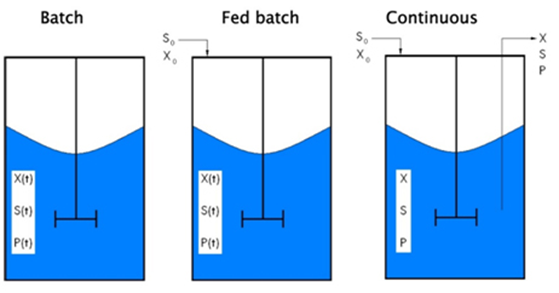

- Proven technology with fleximode options – fed batch, continuous and Combiferm

- High fermentation efficiency with maximum yields

- Higher alcohol concentration in mash upto 15% v/v

- Allows maximum stillage recycle (upto 60% for sugar syrup) reducing substantial water usage and less stillage volume for final treatment

- Option to tap CO2 for processing to food grade quality

Synchronous (Fed-Batch)

HiFerm Fermentation

- Proven technology with fleximode options – fed batch, continuous and Combiferm

- High fermentation efficiency with maximum yields

- Higher alcohol concentration in mash upto 15% v/v

- Allows maximum stillage recycle (upto 60% for sugar syrup) reducing substantial water usage and less stillage volume for final treatment

- Option to tap CO2 for processing to food grade quality

HiFerm Fermentation

Highlights

- Separation of yeast growth phase (Biostat) and ethanol generation phase (Chemostat) in fermenter

- Ensuring hygienic operations in Biostat by operating fermenter in fed batch mode

- Ethanol generation in continuous mode of operation (Chemostat) for consistent mash feed to distillation

Advantages

- Requires lower foot print (by 10-15% compared to fed-batch)

- Reduced CAPEX & OPEX without compromising quality

- Capacity enhancement (15-20%)

- Low CIP effluent generation

- Reduction in spent wash (higher ethanol titer 10-15% v/v)

- Reduced time for construction & commissioning

- Higher fermentation efficiency

- Excellent congener profile for beverage grade alcohol